Track components are fabricated from cold formed steel.

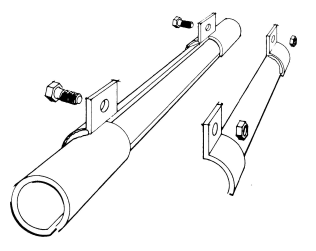

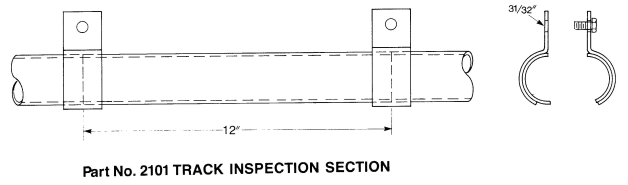

Track Inspection Station: As illustrated below, the inspection section has a removable side for easy access to the chain for inspection and maintenance. It is advisable to install one track inspection section for every 200 feet of conveyor. An inspection every 200 feet also makes installing the chain much easier.

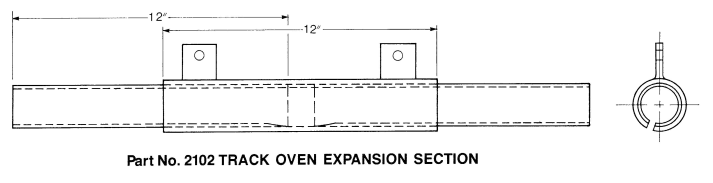

PART NO. 2102

Track Over Expansion Section: This unit is an inline track adjustment section wherein the central "sleeve" section is externally supported to the superstructure and the two (2) tube sections at either end welded to the respective track sections leaving a 1/4" to 5/8" gap at the center. This gap allows the track to expand and contract without deformation.

Each section of straight track passing through an oven should have an oven expansion section. Additionally, any section of straight track subject to ambient temperature changes exceeding 150° F should be fitted with an expansion section.

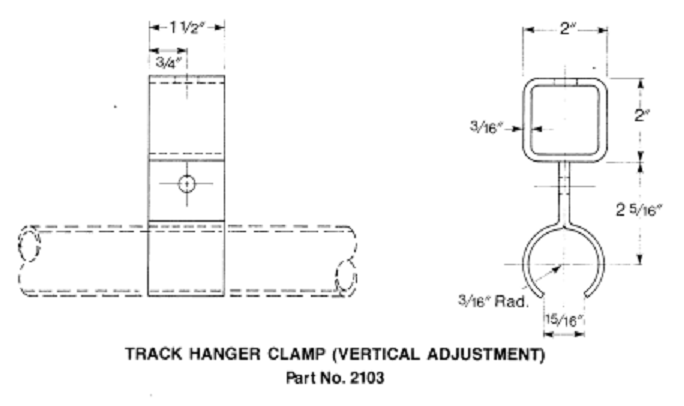

PART NO. 2103

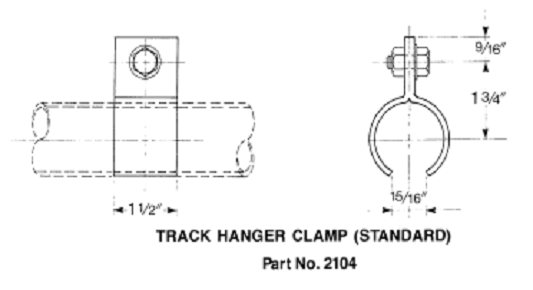

PART NO. 2104

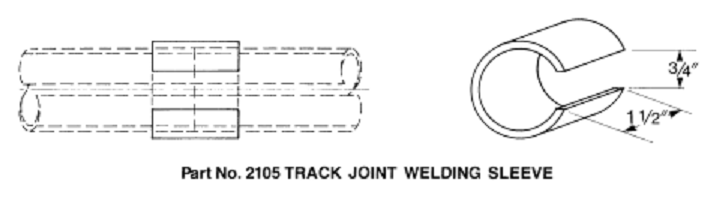

PART NO. 2105

Track Joint Welding Sleeve: One is required at each junction of track, curves, idler sprockets, etc.

PURCHASING DESCRIPTION

General form: Part No./Description

example: Part No. 2101 - Track Inspection Section

Copyright © 1stSource Products, Inc. All Rights Reserved