EXTENDABLE / FLEXIBLE CONVEYORS

Wheel conveyors are also useful in extendable / flexible telescoping versions for today's warehousing operations. Their extendable and retractable qualities are especially useful in loading and unloading trucks, trailers, railroad cars, etc.

SKATE WHEEL CONVEYORS

The primary application for skatewheel conveyors is for handling extremely light-weight unit loads, or when portability is a factor. Skatewheel Conveyors are light-weight, generally inexpensive and loads tend to maintain their orientation while being conveyed... even around curve sections.

Any object having a solid and reasonably firm bottom can be conveyed on skatewheel conveyors. Typical of these are boxes, cases, wood or metal trays, fiber cartons, etc. Containers with cleats, open or recessed bottoms, or any soft materials which would allow indentation by the wheels are not generally practical. Conveyor widths should be chosen so at least four wheels are under the load at all times and the widest load does not overhang the conveyor more than 25% of the conveyor width.

Grades required for gravitation on skatewheel conveyors will vary widely with respect to many variables. Normally, the average carton will convey satisfactorily with the conveyor pitched at 3" per 10'-0" section or 90° curve.

ROLLER CONVEYORS

Roller conveyor is the heart of the conveyor industry. A basic knowledge of its application will carry through many other types of conveyors. To correctly specify roller conveyors, one must consider the following:

1) What is the footprint of the load? That is, what does the surface of the load look like to the rollers. How much does the load weigh? The load must have a smooth conveyable surface.

2) From the footprint, determine the conveyor width. If the rollers are to be set high, make sure the widest load does not overhang the conveyor more than 25%. If rollers are to be set low for the guard rail effect, allow at least one inch on each side of the widest load if the conveyor is straight; more if the load is to negotiate curves.

3) Determine the roller capacity and spacing required. Make sure at least 3 rollers are under the load at all times and, based on the length of the load and the weight of the load and the roller spacing required, determine the roller capacity needed. Allow extra capacity if loads are to be "shock-loaded" that is, dropped onto the conveyor.

4) Take into consideration the operating conditions. Adjust for external factors, dust-protected bearings should be used in abrasive atmospheres, plated bearings would be necessary in damp areas, etc.

5) Choose a frame member that will support the weight of the load under it's maximum condition.

Note: Standard Frame/Roller Assemblies are recommended unless conditions dictate use of an Alternate Frame style. Selection of an Alternate Frame style may result in increases in cost and delivery time.

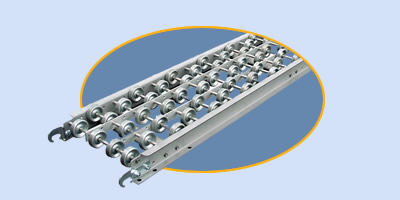

FLOW RAIL

Flow rail is particularly useful in handling wide products, such as sheet steel, plywood sheets, etc. and especially functional in live storage of cartons and boxes. Typically constructed of wheels bolted to angle irons, single lane versions and multi-lane versions with or with-out guard rails can be adapted to convey practically any product that may be handled on conventional wheel conveyor.

BALL TRANSFERS

Normally used in conjection with roller or wheel conveyors to permit manual right-angle transfers or manual orientation of loads, ball transfers can be also useful in handling wide articles such as steel plates, etc. where total movement flexibility is essential. Available are ball transfer tables, ball units mounted on a steel plate, ball modules, which can be bolted directly into a conveyor frame, and ball pedestals which mount directly on the floor.

Copyright © 1stSource Products, Inc. All Rights Reserved